INTRODUCTION

Electrochemical gas sensors are a cornerstone of modern gas detection technology. Their widespread adoption across industries—from environmental monitoring and industrial safety to medical diagnostics—is driven by their high sensitivity, selectivity, low power consumption, and cost-effectiveness. These sensors operate by generating a current proportional to the concentration of a target gas, typically in the nanoampere (nA) range. To accurately interpret this signal, a potentiostatic circuit is required. This circuit maintains a constant potential between the sensing electrode and the reference electrode, enabling precise control of the electrochemical reaction. The resulting current is then converted into a voltage or digital signal for further processing. As the market evolves, engineers are faced with a growing choice of electronic boards and modules tailored for electrochemical sensors. This white paper explores the key considerations in selecting and integrating electronics for electrochemical gas sensors, helping accelerate your time-to-market and improve system performance.

POTENTIOSTATIC CIRCUIT: THE HEART OF SENSOR ELECTRONICS

At the core of any electrochemical sensor system lies the potentiostat. Its primary functions are:

- Maintain a stable potential between the reference and sensing electrodes.

- Drive the counter electrode to balance the current generated by the gas reaction.

- Enable accurate current measurement, which is directly proportional to gas concentration.

Modern potentiostats are implemented using operational amplifiers (op-amps) in a feedback configuration. The design must ensure:

- Low input bias current to avoid distortion of the nA-level signals.

- High common-mode rejection to minimize noise.

- Stable temperature performance for consistent readings.

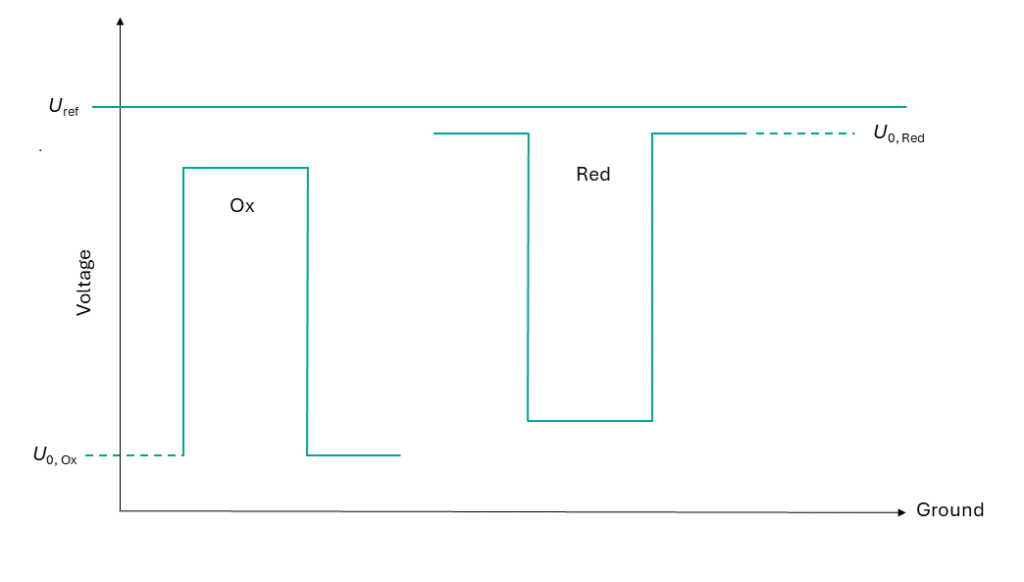

Modern potentiostats also allow an easy selection of zero point, gain or bias voltage settings. A common difficulty is the understanding of the zero-point setting. The current generated in the electrochemical reaction is converted to voltage and needs to “fit” into the corresponding potential well. The output voltage generated by an operational amplifier can be expressed as

follows

Uout=U0+ R Gain∙ I Sensor=U0+ R Gain ∙ S Sensor∙[X]

Uout describes the output voltage, U0 the zero-point voltage, RGain the gain resistance amplification and ISensor the sensor output in nA, respectively. Latter can be calculated from the sensitivity SSensor (typically expressed in nA/ppm) and the applied gas concentration [X].

Most saturation effects which are observed arise from wrong settings for U0 or RGain. For reduction reactions (e.g. NO2 or O3) the zero-point is typically set to a high value because the generated voltage is negative (i.e the sensor current has a negative sign). If U0 is set to a low value, the generated potential cannot be fit into the potential well between ground and Uref, which is typically the supply voltage for the operational amplifier. Similarly, if a sensor generated a large output and the gain is too high, the generated voltage will exceed Uref.

ANALOGUE OR DIGITAL ELECTRONICS?

When selecting electronics for your sensor, one of the first decisions is whether to use analogue or digital signal processing:

Analogue Electronics

- typically include a transimpedance amplifier (TIA) to convert current to voltage.

- offer low latency and high resolution.

- require external ADCs and microcontrollers for digital interfacing.

- are ideal for custom designs or when high precision is needed.

The standard interface is a 4…20 mA output in a two-wire configuration. This allows for an easy implementation in many instruments and has the big advantage of being easy for troubleshooting. The biggest disadvantage is the limited information content. This setup only allows to transfer the sensor output. Temperature compensation curves, numbers of working hours or other diagnostic parameters are not accessible. Furthermore, analogue transmission tends to be susceptible to electrical noise and interferences causing disturbances in the output signal.

Digital Electronics

- integrate the potentiostat with on-board ADCs, microcontrollers, and communication interfaces (e.g., UART, I2C, SPI).

- simplify integration into embedded systems.

- often come with calibration routines, temperature compensation, and diagnostics.

- are suitable for rapid prototyping and mass production.

Digital boards offer a variety of possibilities and are especially suitable for fast tests, IoT-applications and implementation into larger networks. The biggest advantage of digital electronics is the possibility of transferring multiple information content and even remote accessing measurement points.

When choosing or designing electronics for electrochemical sensors, consider the following:

- Current Range: Ensure the TIA and ADC can handle the expected current range (typically 1 nA to 1 μA).

- Resolution: Higher ADC resolution (e.g., 16-bit or 24-bit) improves sensitivity.

- Noise Performance: Low-noise design is critical for accurate detection at low concentrations. This is especially the case for air quality monitoring applications.

- Temperature Compensation: Electrochemical gas sensors have an intrinsic temperature-dependence. Compensations are necessary to measure accurately along the entire temperature range. Electronics need to compensate accordingly. Its noise behavior affects the reading.

- Power Consumption: A reduced power consumption is especially important for portable devices running on batteries or power banks. Gas sensors requiring a bias voltage between reference and sensing electrodes often need an electronic board with additional batteries because the potential difference needs to be kept constant even when the device is off.

- Size and Form Factor: Must fit within the mechanical constraints of your product.

- Communication Interface: Match with your system architecture (e.g., Bluetooth, RS485, Modbus).

Selecting the right electronics for electrochemical sensors is crucial for achieving accurate, reliable, and efficient gas detection. Whether you opt for a custom analogue design or a plug-and-play digital module, understanding the underlying principles and trade-offs will empower you to make informed decisions. By leveraging modern electronics, you can

reduce development time, improve measurement accuracy, and ensure compliance with industry standards—ultimately delivering better products to market faster.

Membrapor, a Swiss manufacturer of electrochemical sensors, has a wide selection of electronic boards in their portfolio including services such as calibrations. As a part of the value proposition, they offer consulting during the design or prototyping phase to increase time-to-market.